Multilayer Label Converting Technology – Producing Sandwich Labels (made easy)

Do you want to produce multilayer labels without investing in a new converting line? Then you are like many of our customers looking for a cost-efficient solution to print multi-layered sandwich labels or peel-offs. That is why we developed our Multilayer Label Converting Kit as an extension for your label printing press to produce high-quality labels with up to three layers on your existing equipment. A space-saving extension for your machine and a big step for your business.

Multilayer Label Converting Technology for Your Label Printing Press

Do you want to produce multilayer labels without investing in a new converting line? Then you are like many of our customers looking for a cost-efficient solution to print multi-layered sandwich labels or peel-offs. That is why we developed our Multilayer Label Converting Kit as an extension for your label printing press to produce high-quality labels with up to three layers on your existing equipment. A space-saving extension for your machine and a big step for your business.

Features

- Multilayer label converting technology to produce complex multi-layered labels

- Joining of up to 3 layers of adhesive material webs

- Integrated solution for non-contact web handling

- Extension for your existing label printing press

More advantages

- Most space-saving assembly design on the market

- Compatible with any label printing press or converting machinery

- Simple and fast installation

- Durable and reliable

- Intuitive operability

Areas of application

- Producing sandwich labels for fast moving consumer goods, food, cosmetics, pharmaceutical products, etc.

- Multilayer labels for industrial goods

- Peel-off labels or wrap-arounds

- for label printing companies and packaging machine manufacturer

Plug & Play technology

- No electrical connection necessary

- No adjustment of the machine control necessary

- Seamless integration into or between your existing label printers and converting machines

- available in different sizes

(see technical data)

From Label Printing to Multilayer Label Converting

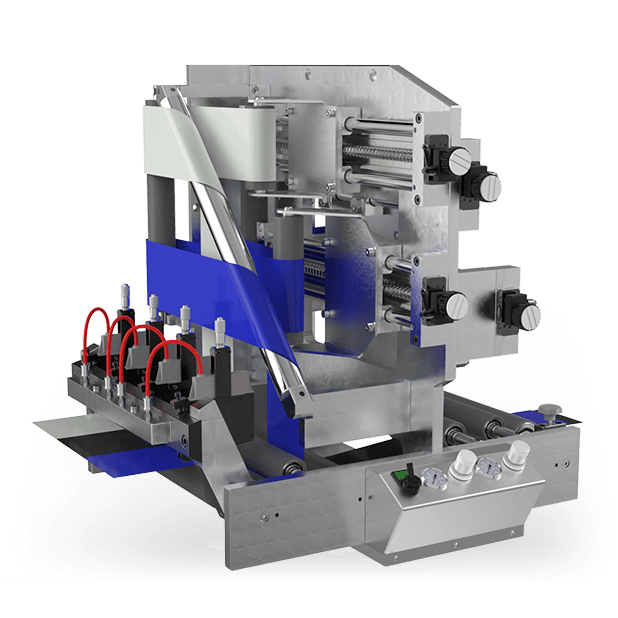

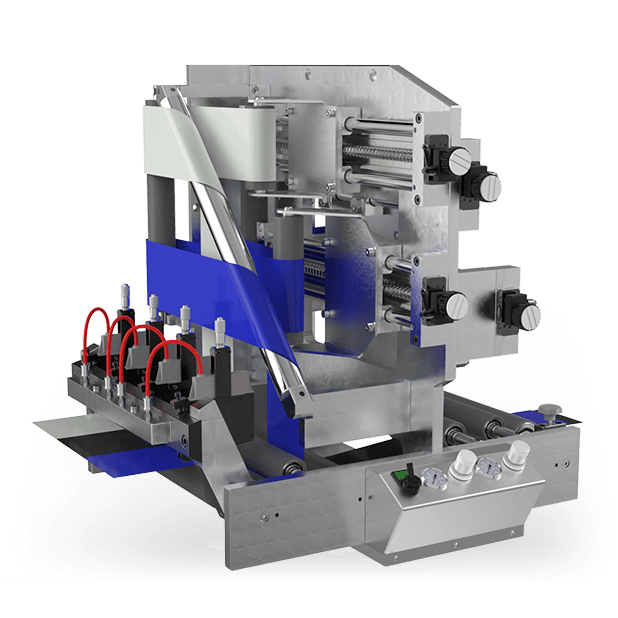

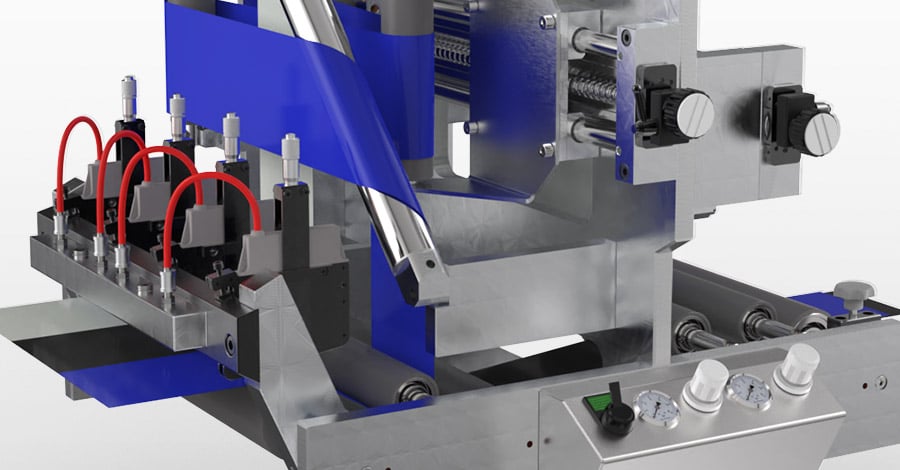

When producing multilayer labels, several material webs are laid on top of each other and merged. Ultimately, the multilayer web is die-cut into the final label shape. The Multilayer Label Converting Kit transforms your classic label printing presses into innovative web converting systems for the smooth roll-to-roll processing of various layers to be joined. The advanced web handling system seamlessly feeds multiple layers of adhesive material webs on top of each other, enabling you to produce sandwich labels with up to three layers on your existing equipment.

Why produce multilayer labels?

Product packaging is what consumers look at in stores before they decide whether to buy a product or not. Therefore, label quality, design, and usability are crucial, especially in the pharmaceutical and FMCG industries (fast-moving consumer goods). Multilayer labels, also called sandwich labels, offer a variety of uses for information and advertising on product packaging. They provide long-term benefits and can help build customer loyalty. Most label printing companies and packaging machine builders have long since upgraded to produce multi-layered sandwich labels … what about you?

Plug & Play for your existing production line

The compact inline extension can quickly be mounted and installed in or between your existing printing presses and machines and fits seamlessly into your usual production line. It enables robust multilayer web converting processes in the smallest space and is suitable for a wide range of applications that ensure optimum utilization of your plant. You benefit from low susceptibility to faults, intuitive operation, and an unbeatable price/performance ratio. As a result, your portfolio expands, paving the way for more business opportunities at manageable investment costs.

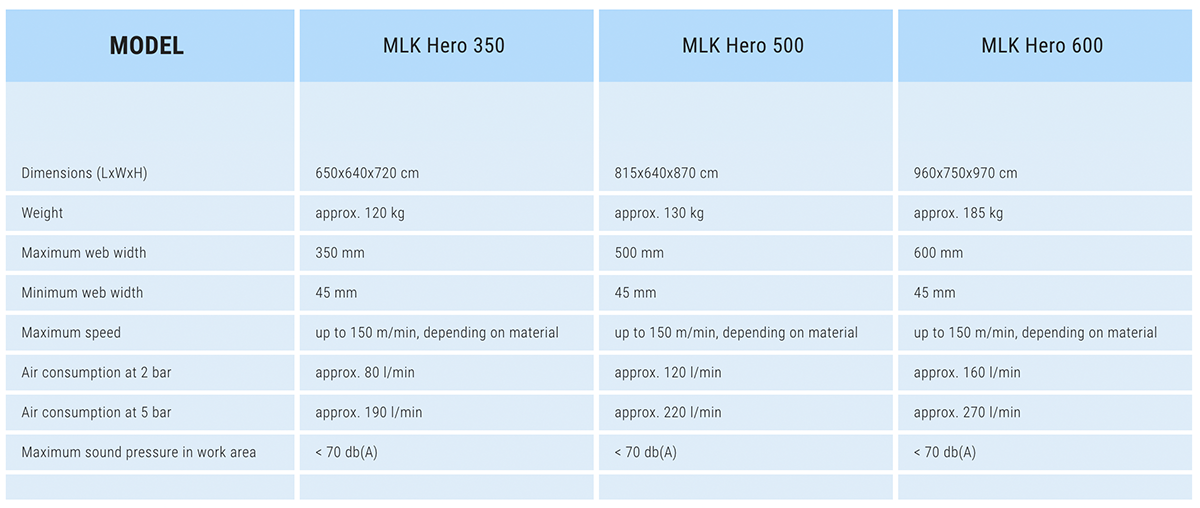

SPECS

-

Dimensions (LxWxH)

-

Weight

-

Maximum web width

-

Minimum web width

-

Maximum web speed

-

Air consumption at 2 bar

-

Air consumption at 5 bar

-

Max. sound pressure in work area

-

Model 350

-

650x640x720 cm

-

ca. 120 kg

-

350 mm

-

45 mm

-

up to 150 m/min, depending on material

-

ca. 80 l/min

-

ca. 260 l/min

-

< 70 db(A)

-

Model 450

-

800x710x820 cm

-

ca. 120 kg

-

450 mm

-

45 mm

-

up to 150 m/min, depending on material

-

ca. 120 l/min

-

ca. 350 l/min

-

< 70 db(A)

-

Model 600

-

935x710x970 cm

-

ca. 185 kg

-

600 mm

-

45 mm

-

up to 150 m/min, depending on material

-

ca. 160 l/min

-

ca. 480 l/min

-

< 70 db(A)

-

The Multilayer Label Converting Kit in Use

Download product sheet

Download Printum’s Multilayer Label Converting Extension product information sheet, or contact us to learn more about our web converting equipment.

Any questions left? Give us a call!

Would you like to produce multilayer labels with our Multilayer Label Converting Technology? We will be happy to answer your questions about the Multilayer Label Converting Extension or other converting products by Printum. Please contact us without obligation.

Andreas Weigel

Managing Director

Sales